Product Description

Built upon the proven technology of Mimaki’s industry-leading flatbed printer, the JFX200-2513 EX offers expanded capabilities with greater productivity and functionality. New features include a draft mode that enables a maximum print speed of up to 12 boards per hour and three staggered printheads that allow for simultaneous printing without sacrificing speed, even when using white and clear inks. This model offers faster mechanical motors and a vacuum foot pedal, giving the user the ability to load or unload various substrates quicker and more effectivity.

Benefits of the Mimaki JFX200-2513 EX

- Landscape-oriented table can print on one 4’ x 8’ board or a variety of pre-cut pieces, and onto objects up to 2” thick

- Dual-zoned vacuum table and user-adjustable layout pins

- Nozzle Recovery System and Nozzle Check Unit

- Variable Dot Technology and Mimaki Advanced Pass System (MAPS) for smooth gradients and solids

- Greenguard Gold UV-LED inks in 4 and 6 color configurations plus Clear, Primer and White

- Updated RasterLink6 Plus to support 2.5D textured print workflows

- USB/Ethernet connectivity

Highlights of the Mimaki JFX200-2513 EX

2.5D Print Function Enables Easy Creation of Textured Graphics

Compatible with RasterLink6 Plus software, 2.5D printing allows users to create dimensional textured graphics up to 0.5 mm in height using greyscale. These semi-stereoscopic graphics, such as a beveled polygon or a bowl shapes, add a new look and feel to the finished application, enhancing its appearance while increasing its value. Combined with Mimaki Clear Control, this print function also takes full advantage of Mimaki’s LUS clear inks to remove bubbles and create sharper edges, delivering textured graphics that look and feel like the objects being represented.

Landscape-Oriented Table

The landscape-oriented table can print an entire 4-foot by 8-foot piece, or print multiple smaller boards using the two selectable vacuum zones. It can also print to pre-cut, irregularly-shaped pieces.

Layout Pins

Standard layout pins and scale ensure board alignment, which is particularly useful when printing full bleeds.

Variable Drop Printing

The advantage of variable drop printing is most apparent when printing color gradations in light or pastel colors.

Anti-Banding Technology

Variable drop printing combined with Mimaki Advanced Pass System technology ensures precise and accurate print quality throughout the printing process, greatly reducing the appearance of banding and resulting in a smoother image.

White, Primer and Clear

Add White ink to print onto clear acrylic to create backlit panels or to print on wood, metal, or non-white surfaces. Mimaki Circulation Technology regularly circulates White ink between the supply and the printhead to prevent settling. Primer helps the ink adhere to surfaces such as glass. Clear ink adds ‘pop’ and protection to finish a piece.

UV-LED Technology

Mimaki’s UV-LED system uses less energy than other UV types, has a longer life and can print into media that could be damaged by higher-heat systems.

Direct-to-Media Printing Even on to Thick Media

Images can be printed directly onto rigid media up to 50mm thick, providing great versatility and a wider range of potential applications.

What you can do with the Mimaki JFX200-2513 EX

- Signs and posters

- Point-of-purchase displays

- Exhibition graphics/signs

- Backlit panels

- Interior decor

- Packaging prototypes

- Specialty and industrial applications

- Acrylics

- Polycarbonates

- PVC

- Glass

- Aluminum

- Metal

- Polyester

- Foam board

- Styrene

- Wood

- Stone

- and more…

Attention should be paid to ink adhesion, even though it will print onto almost any substrate, levels of adhesion do differ between materials. The range of possible applications is practically limitless. A selection:

- Art reproduction

- Backlit graphics

- Construction signs

- Displays

- Rigid packaging

- Lenticular (printing with 3D effects)

- ID cards

- Logos (3D)

- Operation panels

- Promotional items

- Relational gifts

- Accessories

Technical overview of the Mimaki JFX200-2513 EX

| Print system | On-demand piezo (3 printheads in a staggered configuration) |

| Max print area | 98.4” W x 51.1” L (2500 x 1300 mm) |

| Media thickness | 1.96 in (50 mm) |

| Print resolutions | 300, 450, 600, 900, 1,200dpi |

| Max print speed | 376 SqFt/Hr (35 SqM/Hr) / in draft mode |

| Absolute accuracy | +/- 0.01” (0.3 mm) or +/- 3% from specified print distance |

| Repeatability | +/- 0.008” (0.2 mm) or +/- 1% from specified print distance |

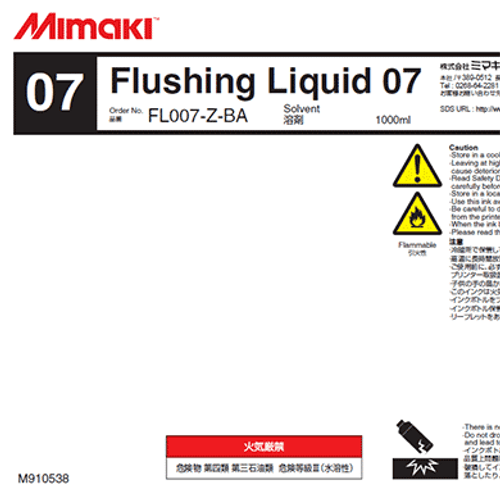

| Ink type | Mimaki LUS-150 UV ink: For balanced adhesion and flexibility- C, M, Y, K, Lc, Lm, W, Clear Mimaki LUS-120: For flexibility and scratch resistance- C, M, Y, K, W, ClearMimaki LUS-350: Up to 350% elongation for thermoforming applications- C, M, Y, K, W, Clear Mimaki LH100 UV ink: For high scratch and chemical resistance- C, M, Y, K, W, Clear* Mimaki PR-200 UV Primer |

| Ink capacity | 1-liter bottle, 250 mL bottle |

| Flatbed table | Vacuum system (standard), 2 user-selectable zones Layout pins and lonizer (standard) |

| Certifications |

VCCI Class A, FCC Class A, ETL UL 60950 CE Marking (EMC, Low voltage, Machinery directive) CB Report, RoHS |

| Operational environment | Temp: 59˚ – 86˚ F (15˚ – 30˚ C) |

| Max media weight | 110.2 lb / SqFt (250kg/SqM) |

| Interface | USB 2.0, Ethernet |

| Power supply | AC 200-240V, 50/60 Hz |

| Power Consumption | 2.88 kVA |

| Dimensions (W x D x H) | 173.2 x 96.4 x 49.2 inches (4,400 x 2,450 x 1,250 mm) |

| Weight | 1433lbs. (650 kg) |